Type of project

Product development through rapid prototyping

Context

Hobby project for Instructables.com contest entry

Year

2020

This project was about designing concrete moulds that could be 3D printed and reused between each cast. Two different moulds were designed, one for a candlelight and one for a bowl.

The project was a submission in an Instruclables.com contest under the theme of "Stone, Cement and Concrete". The project did not win but can be seen at www.instructables.com/3D-Printing-Concrete-Molds/

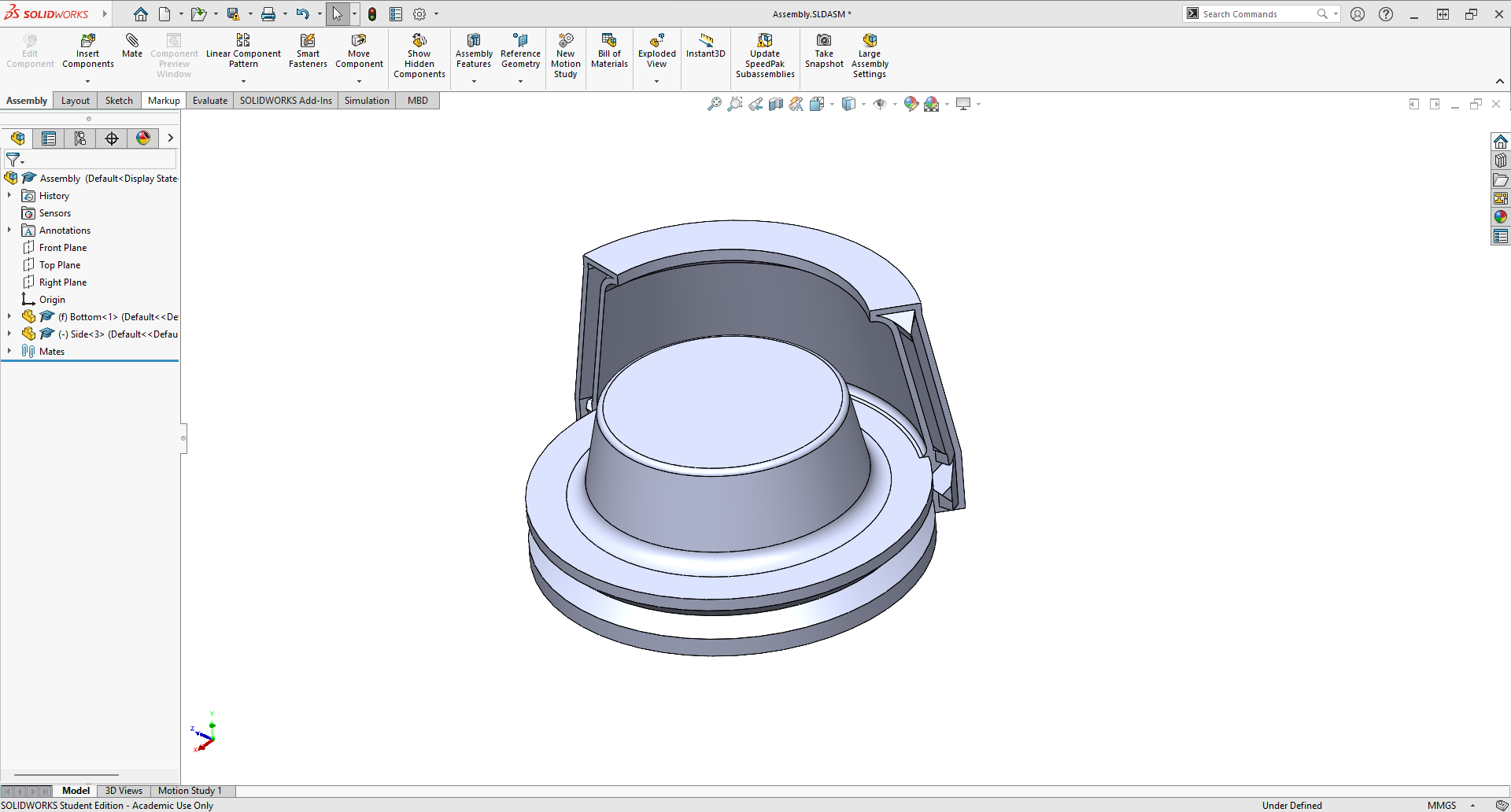

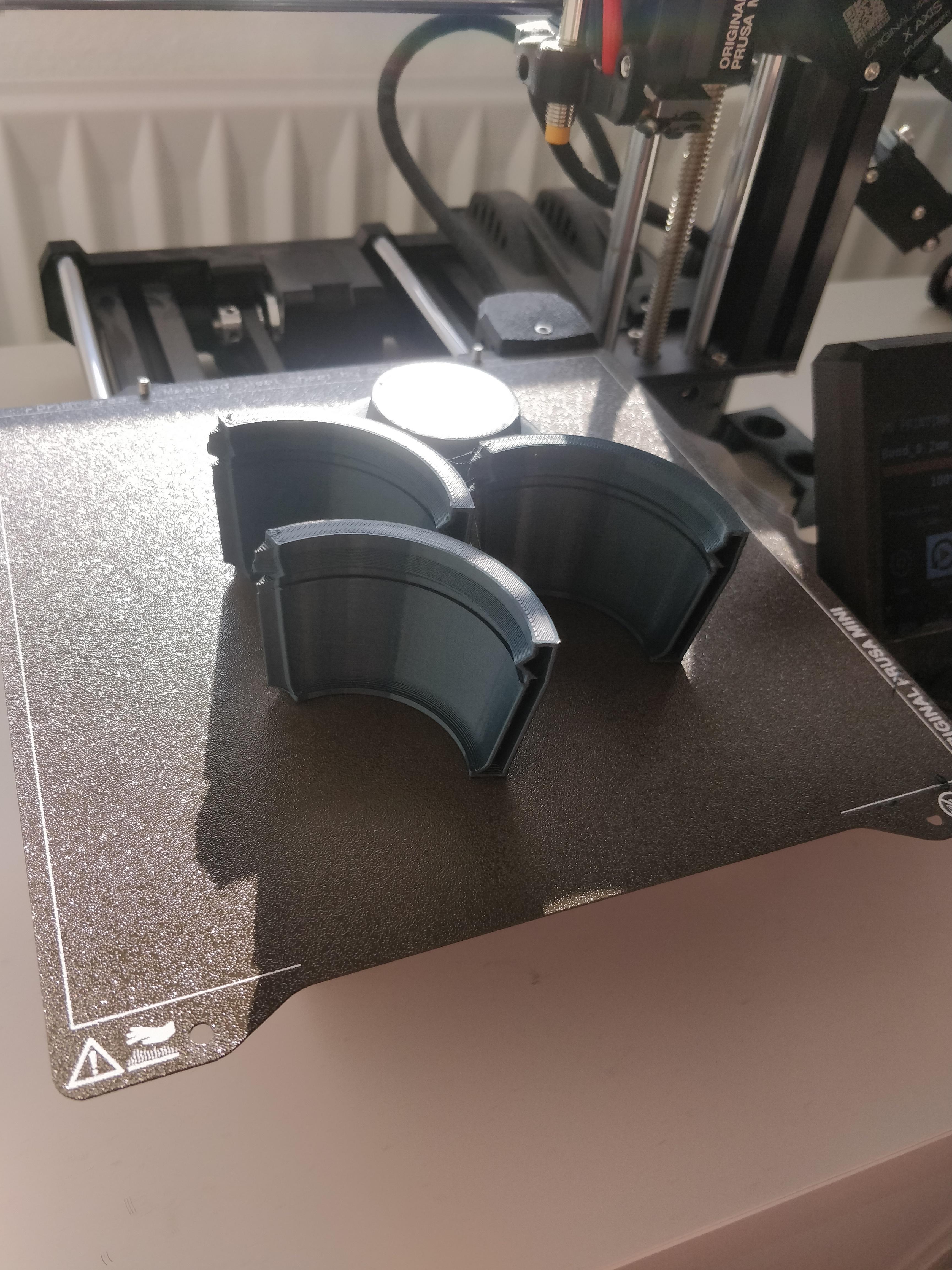

The mould was made in Solidworks with a design that had enough of an angle that the mould would easily come off once the cast was finished. Additionally, the parts all had grooves and taps to keep the mould tightly together when pouring the concrete.

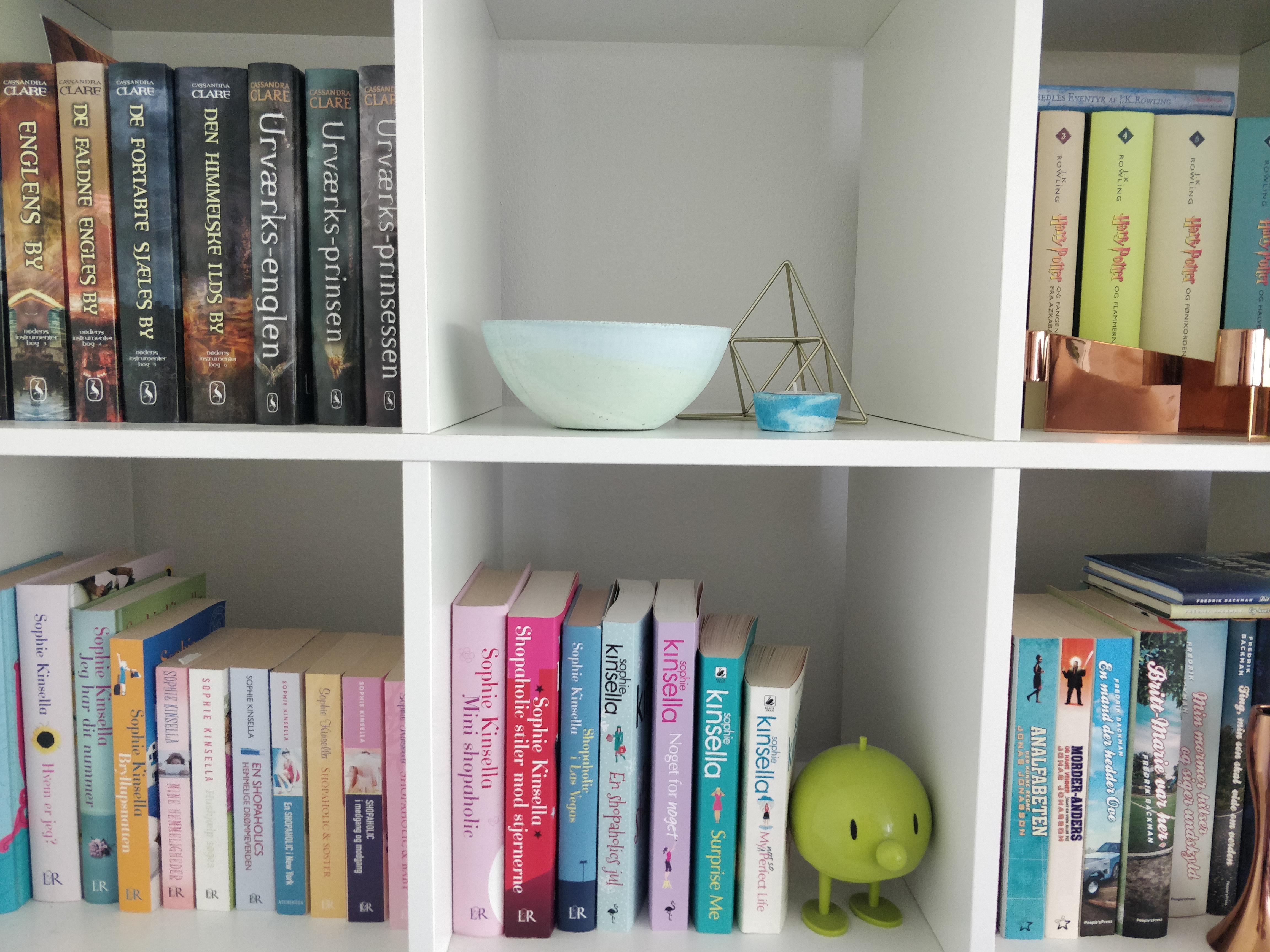

Color was added to the concrete to showcase that a lot of different looks were available with the same mould, simply by changning the color and by changing how the color is stirred in.

Once the concrete is set the walls can be removed to sand the cast. Once that is done the cast can receive surface treatment with a sealer.

The biggest challenges in the project was figuring out how big of an angle the moulds should have to release the cast. This was more challenging than anticipated since the 3D print leaves small grooves for each layer that is printed. This was partly negated by sanding the mould before casting to smooth out the surface. Overall the project was a huge success despite not winning the competetion.